Standards on packaging for terminally-sterilized medical devices updated

Revisions of ISO 11607 Parts 1 and 2 completed

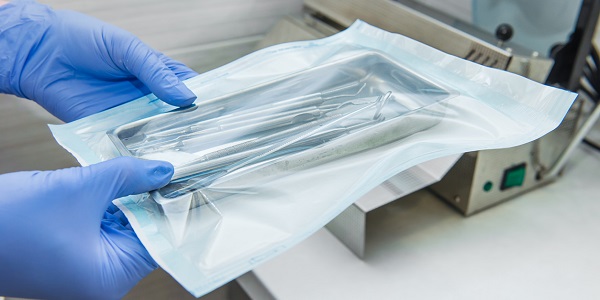

New editions of the ISO 11607 series of standards on packaging for terminally-sterilized medical devices have been completed. The ISO 11607 series of standards comprise:

- ISO 11607-1 - Packaging for terminally sterilized medical devices — Part 1: Requirements for materials, sterile barrier systems and packaging systems; and,

- ISO 11607-2 Packaging for terminally sterilized medical devices — Part 2: Validation requirements for forming, sealing and assembly processes.

The European adoptions of the first editions of the ISO 11607 series of standards were harmonised for the European Directives for medical devices.

- EN ISO 11607-1:2017 is the European adoption of ISO 11607-1:2006 incorporating its 2014 amendment;

- EN ISO 11607-2:2017 is the European adoption of ISO 11607-2:2006 incorporating its 2014 amendment.

The new editions of these standards incorporate the amendments to the standard introduced in 2014, introduce technical revisions and replace the earlier editions of the standards. In particular, the revisions of the standard have included changes to incorporate the increased emphasis on the sterile barrier system for sterile medical devices that have been included in the European Medical Devices Regulation.

The main changes in the new edition of ISO 11607-1 compared to the previous edition are:

— the definitions have been aligned with the 2018 edition of ISO 11139 - Sterilization of health care products — Vocabulary of terms used in sterilization and related equipment and process standards;

- new requirements for the evaluation of usability for aseptic presentation of the medical device have been added;

- a new section with requirements for revalidation in accordance with ISO 11607-2 has been added;

- the Annex on test methods has been updated with various international test methods being added or deleted;

- a new Annex with environmental considerations has been added;

- a new Annex with guidance on ways to differentiate a sterile barrier system from protective packaging has been added.

The new edition of ISO 11607-1 points out that it is best practice to inspect sterile barrier systems immediately prior to use to determine if breaches in integrity of the barrier are evident. The standard indicates that the instructions for use for sterile medical devices should include inspection for breaches of the integrity of the package prior to use.

The main changes in the revision of ISO 11607-2 compared to the previous edition are:

- terms and definitions for “process variable”, “process parameter” and “monitoring of processes” have been added and all definitions have been aligned with the latest version of ISO 11139;

- the terminology of “critical” process parameters has been discontinued and the concept of a process specification has been introduced to include all elements required to manufacture a product that consistently meets specifications.

The updated edition of ISO 11607-2 also supports the explicit requirement for validation of the sealing of the sterile barrier system in ISO 13485:2016 - Medical devices — Quality management systems — Requirements for regulatory purposes.

The revisions of ISO 11607 will be adopted as European standards. These new editions incorporate features intended to support the Medical Devices Regulation. Manufacturers of sterile medical devices should review the changes in the new editions of the standard and identify any gaps that they need to close.

Author: Eamonn Hoxey, of E V Hoxey Ltd, UK, is a writer, trainer and consultant on a range of life science areas including regulatory compliance, quality management, sterility assurance and standards development

Request more information today for a call back from a member of our sales team so that you can get a better understanding of how Compliance Navigator can meet your needs.

The Compliance Navigator blog is issued for information only. It does not constitute an official or agreed position of BSI Standards Ltd or of the BSI Notified Body. The views expressed are entirely those of the authors.