Designating of medical devices as sterile and the MDR

The EN 556 series of standards defines requirements for designating device as sterile

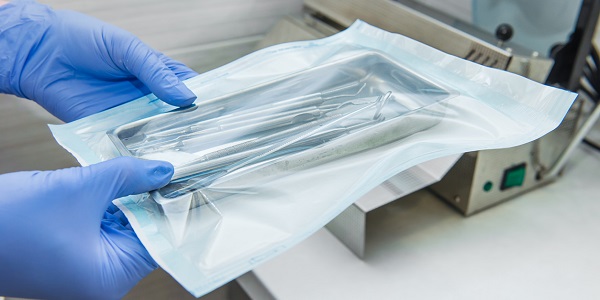

The European Medical Devices Regulation 2017/745 (MDR) presents requirements for sterile devices but does not provide a definition of the term ‘sterile’. Sterile devices are free of viable microorganisms. The EN 556 series of standards defines requirements for designating devices as sterile. Parts 1 and 2 of EN 556 provide requirements for terminally sterilized devices and aseptically produced devices respectively.

EN 556-1 is the European standard specifying requirements for designating a terminally-sterilized device as sterile. It has also been adopted in a number of countries outside Europe, for example Australia and China. EN 556-1 specifies that a probability of a viable microorganism on a device of 10−6 or less (e.g. 10−7, et seq.) has to be achieved in order to designate a terminally sterilized medical device as sterile. The probability of survival of a single microorganism is also known as the sterility assurance level (SAL).

There can be, however, devices that are unable to withstand a terminal sterilization process achieving this probability. This might be because some or all of the materials that constitute the device are sensitive to traditional sterilization processes, for example cellular or biologically based components. EN 556-1 includes an explanatory note that indicates that permission for acceptance of a probability greater than 10−6 (e.g. 10−5) can be sought through appropriate regulatory bodies. Such permission requires consideration of the individual situation, including the risk assessment undertaken by the manufacturer of the device. However, EN 556-1 gives no guidance on criteria that might be considered in seeking such approval and there is no alignment on how such devices should be labelled.

ISO/TS 19930:2017 provides:

- background information on assurance of sterility and sterility assurance level

- guidance on strategies that can allow the achievement of a maximal SAL of 10−6

- general guidance on the considerations to be taken into account in selecting a SAL for a health care product that is unable to withstand terminal sterilization to meet the general requirement to achieve maximally a SAL of 10−6

ISO/TS 19930 has not yet been adopted as a European Standard. It is a guidance document and not intended to provide any presumption of conformity with European regulatory requirements. This topic is contentious for some regulatory agencies, conformity assessment bodies, manufacturers and national standards bodies. This TS does not relax the regulatory and quality requirements to supply product as sterile. Its purpose is to bridge a gap in existing standards and regulations. ISO/TS 19930 provides guidance on technical aspects when considering an alternative SAL to 10−6 for identified high clinical need, terminally sterilized devices unable to withstand the processing conditions necessary to achieve maximally a SAL of 10−6.

When terminal sterilization is not possible, aseptic processing provides an alternative means of achieving a sterile device. Aseptic processing is based on preventing contamination of sterile items. Aseptic processing is not based on inactivation of microorganisms and so the concept of extrapolation of a probability of survival of a microorganism does not apply. EN 556-2 provides requirements for designating an aseptically processed medical device as sterile. The EN ISO 13408 series of standards provide means to support conformance with EN 556-2.

This is an excerpt from the forthcoming BSI medical devices white paper: Sterilization – Regulatory requirements and supporting standards. To browse our collection of medical device white papers, please visit the Insight page on the Compliance Navigator website.

Request more information today for a call back from a member of our sales team so that you can get a better understanding of how Compliance Navigator can meet your needs.

The Compliance Navigator blog is issued for information only. It does not constitute an official or agreed position of BSI Standards Ltd or of the BSI Notified Body. The views expressed are entirely those of the authors.