Biomedical applications of 3D printing pt.1

Surgical guides are a key biomedical application of 3D printing

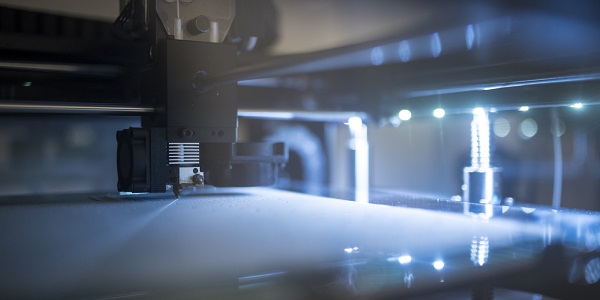

3D printing gives the ability to produce physiological shapes from 3D imaging techniques in a wide range of materials. This has opened up the ability to create medical devices in geometries which would be difficult to create using other manufacturing techniques, and the research literature offers many examples of innovative devices and associated clinical case studies. 3D printing is also extensively used for producing prototypes as part of product development, and applications of 3D printing to making models for surgical planning or to inform clinical or patient decision making, both of which are important and valuable applications. The major commercial application areas for 3D printing in biomedical applications have been surgical guides, musculoskeletal implants, hearing aids and orthotics. This is not an exhaustive list, but an outline of the major application areas.

The utilization of medical imaging techniques to provide geometric information with which to design medical devices is a key feature of early medical applications. Materialise, a Belgian CAD/CAM company which produces the Mimics software package was a pioneer in making the link between medical applications and .stl files, and still maintain a significant market presence. Musculoskeletal surgical devices were one of the first commercial applications, allowing clinicians to define in silico where a hole or cut should be made as part of a surgical procedure, and then to have a device produced which would guide a drill or saw to the required position. The work flow is generally (i) to work from a CT or MRI scan and generate a 3D reconstruction of the bone, (ii) to define the holes or cuts relative to that scan and (iii) to define a device which would be uniquely located onto patient landmarks and also provide guidance to the surgical instrument. Once designed, an .stl for the device is produced and the device produced, normally in a polymer, with steel inserts used to reinforce the guide where the drill or saw would be deployed. Surgical guides for dental applications were one of the first applications, but the largest scale application has been guides for total joint replacement, in particular for the knee. The clinical value of guides in complex surgery is clear, with reduced operation times and improved outcomes, but for operations where clinicians are well practiced, the clinical evidence suggests the value is more marginal.

This is an excerpt from the forthcoming white paper The impact and potential for 3D printing and bioprinting in the medical devices industry. To download our other medical device white papers, please visit the Insight page on the Compliance Navigator website.

Request more information today for a call back from a member of our sales team so that you can get a better understanding of how Compliance Navigator can meet your needs.

The Compliance Navigator blog is issued for information only. It does not constitute an official or agreed position of BSI Standards Ltd or of the BSI Notified Body. The views expressed are entirely those of the authors.